Happy Thursday! Welcome to Electric Avenue, the EV newsletter that’s more satisfying than popping bubble wrap.🫧

Here’s what we have for you today:

25% of Global Car Sales are Electric ⚡️

The Tesla Supercharging Flywheel 🎡

3 Links 🔗

Meme of the week 🤡

Not subscribed yet? Sign up here 👇🏼

Let's dive in!

25% of Global Car Sales are Electric ⚡️

More than 25% of all new cars sold globally in 2025 were electric, according to Ember (link). EV adoption is now truly global, with 39 countries above 10% EV share (up from just four in 2019). The biggest shift is that emerging markets—especially ASEAN—are driving growth, with Singapore and Vietnam ~40% EV share. Indonesia reached 15%, overtaking the US for the first time, while Thailand hit 20% and is rapidly scaling. In Latin America, Uruguay reached 27%, and Mexico and Brazil continue steady gains, as Japan stays ~3%. Much of this momentum is powered by Chinese EV exports increasingly flowing to non-OECD markets like Brazil, Mexico, UAE, and Indonesia.

Source: Ember (link)

If you are interested in how Chinese brands were able to gain traction in markets like Mexico, check out our article:

The Tesla Supercharging Flywheel 🎡

2026 unfolds, and the EV charging industry has come a long way when I compare the charging landscape in Germany from 2018 (when I joined the industry) vs. today.

Public fast charging is no longer about who installs the most plugs. It’s about who can deliver reliable throughput at scale, keep costs under control, and shape demand in real time. Over the last decade, Tesla has quietly built a flywheel around these principles—one that compounds advantages across hardware, software, customer experience, and energy.

In this article, we try to unpack the Tesla Supercharging Flywheel and explain why many of its effects remain difficult for other charge point operators (CPOs) to replicate.

Lowest Capex: charging as a product, not a project

Tesla approached charging like mass manufacturing a product, not construction like an infrastructure project.

Most Tesla supercharger sites follow a standardized site layout. This includes centralized power cabinets, relatively tight charging spots to park the car, which means less lease to pay to the landlord, and repeatable design, including pre-fabricated supercharger units to reduce installation timelines and costs.

Large-format sites—sometimes dozens or even hundreds of stalls—further amortize grid interconnection, permitting, and construction works across more chargers. The result is a lower cost per dispenser and a deployment machine that behaves more like a product rollout than an infrastructure project. Based on data from NEVI program bids and Tesla's internal reports, the hardware cost for a Tesla Supercharger stall is approximately $40,000-$45,000, with a target of under $40,000 per stall for V4 chargers (State of Charge). This is significantly lower than the industry average, which often exceeds $100,000 per stall. (paren analysis).

Why this matters:

Most CPOs still operate in a semi-custom world—different hardware vendors, different and inefficient site layouts, different software stacks. Tesla’s replication advantage compounds with every site it builds.

Operational excellence at scale: where the flywheel accelerates

Tesla’s true advantage emerges in day-to-day operations, where multiple levers are controlled within a single system.

Reliability-first operations: Operational expenditure is where many charging networks struggle. Failed charging sessions, broken connectors, stolen cables, and missing uptime drive customer support & maintenance costs and brand damage. Tesla attacks operations from multiple angles:

Large sites reduce the risk of stranded & frustrated customers when chargers are broken. Additionally, larger sites enable operational synergies for field service.

Hardware reliability & remote diagnostics from the Supercharger units (expect their V4 cable holder) and their entire fleet allows Tesla to diagnose problems before the customer notices.

Automated customer flows: Autocharge and native billing through the vehicle account eliminate payment friction and reduce support overhead for Tesla drivers. For the future, we expect that third parties will be enabled to use Plug & Charge authentication (based on ISO 15118-20) at Tesla sites.

AI customer support: It’s almost impossible to talk to a Tesla support employee, as everything is designed for self-service and automated through AI agents to support customers in case there is a problem.

The outcome is a network widely perceived as the most reliable fast-charging option on the market. Fewer failures mean fewer field interventions—and that directly translates into lower ongoing costs.

Intelligent demand management: While the majority of charge point operators struggle with reliable operations, Tesla is already actively managing demand intelligently with two reinforcing demand levers.

Lever: Demand steering — where and when cars charge

Tesla’s in-car routing directs vehicles to available sites and balances utilization across locations to prevent congestion. Additionally, Tesla can quite accurately predict the energy demand on a 15-minute interval, which comes in handy to procure energy on the spot markets, to reduce balancing costs, and purchase solar energy via power purchasing agreements. While Tesla has been publishing their static POI data for superchargers in third-party navigation systems for quite some time, only recently Tesla started to share their dynamic availability data to third parties, including Google (see post on X). I wouldn’t be surprised if they were able to negotiate a backwards channel where Tesla receives ETA times of third-party vehicles using Google’s navigation.

Lever: Intelligent pricing — control demand first, then shape costs.

Tesla does not ask: “What is the cheapest energy right now?” It asks: “How do we maximize usable charging minutes per stall?”

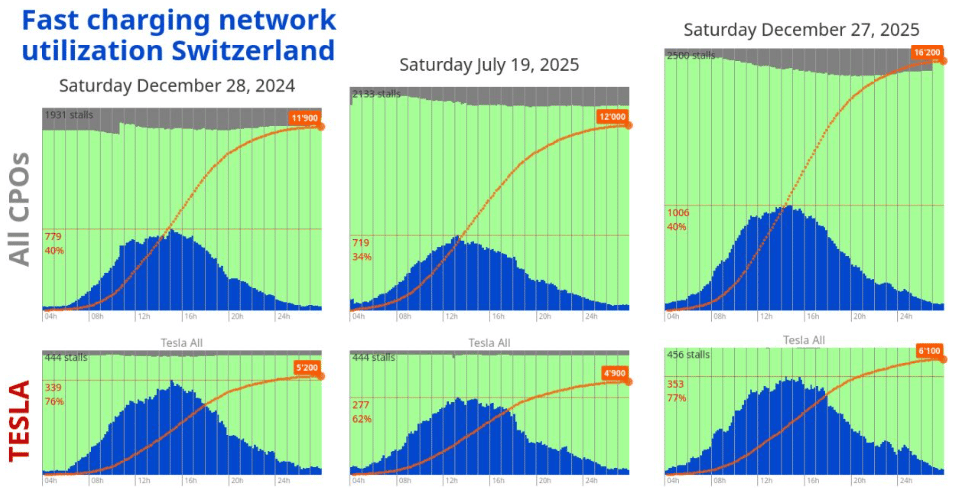

Tesla's time-of-day rates (on-peak and off-peak pricing), congestion fees, and idle fees incentivise customers to remove their cars from the chargers once they have reached 80% SoC, thereby flattening out the utilisation peak and maximizing energy throughput. This enables Tesla to maximise revenue per dispenser hour. Unfortunately, there is no public data to support this effect in detail. However, a recent LinkedIn post shows the impact of reduced off-peak rates in Switzerland at midnight, with a significant increase in utilisation compared to other CPOs during this time.

Source: Clark Winkelmann (link)

Unlike dynamic energy costs, which peak in the morning and evening (see the graph below), when consumers’ demand peaks and photovoltaic production is low, fast charger utilisation mainly occurs during the day, with a peak between 12 pm and 4 pm. Therefore, Tesla’s intelligent pricing is primarily demand-driven. Variable energy costs are reflected on a monthly or quarterly basis, with reduced energy sourcing costs in summer and higher average costs in winter months.

Source: GridX (link)

The final Flywheel → Why this compounds?

Most CPOs operate these levers in isolation. Tesla operates them as a single control system. This is where the flywheel truly compounds, and each rotation strengthens the next:

strong operations → reduce costs and improve customer experience

driving higher utilization → more energy demand

intelligent demand management → better unit economics

capital to expand → even larger, denser network

Each loop strengthens the next.

own illustration

For the sake of electrification, one can only hope the rest of the industry closes the gap—because scaling EV adoption will require more than just more chargers. It will require better systems.

Let me know your thoughts in the comments on LinkedIn.

3 Links 🔗

Rivian with dual battery pack on a cannonball run 🗺: A heavily modified R1T with a dual-battery setup is documented attempting to break the EV Cannonball Run cross-country record by significantly extending range and charging capability (link). Sweet reminder how the Electric Avenue Team set a new WORLD Record on the Cannonball Run with a Lucid Air for the least amount of charging stops (link)

Green light for e-truck charging hubs on German motorways 🚚: The European Commission has approved Germany’s plan to subsidise the rollout of up to €1.6 billion in public fast-charging hubs for heavy electric trucks at unmanaged rest areas along its motorways, allowing the project to proceed under EU state aid rules (link).

Tesla Semi charging with 1.2 MW ⚡: Tesla shared a post of their Semi (electric truck) charging at a rate of 1.2 MW (= 1200kW) with the Megawatt Charging System connector. 😳

Meme of the Week 🤡

🤣🤣🤣

That's a wrap for this week! Let us know how you feel and leave some feedback (We read every single one of these 🙂 ):

What do you think of today´s edition?

Someone forwarded this to you? Subscribe now - it's free!

DISCLAIMER: None of this is financial or tax advice. This newsletter is strictly educational and is not investment advice or a solicitation to buy or sell any assets or to make any financial decisions. The Electric Avenue team may hold investments in or may otherwise be affiliated with the companies discussed.