Sponsored by

Happy Monday. Welcome to Electric Avenue, the only EV newsletter that features a clown emojii in the table of contents 🤡

Here’s what we have for you today:

⚡An inconvenient truth: Why every EV has at least 10% charging losses in the EPA test cycle data

3 Links 🔗

Meme of the week 🤡

Not subscribed yet? Sign up here 👇🏼

Let's dive in!

⚡An inconvenient truth: Why every EV has at least 10% charging losses in the EPA test cycle data

The following is a guest post by Michael Clarke who holds experience at Telsa, Porsche, and Nio building charging services for EU customers. This post outlines the personal opinions and thoughts of Michael and does not necessarily reflect the opinions and views of his employers or Electric Avenue.

What percentage of the energy you are paying for actually gets stored inside of the battery? The facts might surprise you and have serious implications for future charging technologies.

Accurately measuring the real charging efficiency is difficult in everyday life, especially if you want to include all relevant losses. Most efficiency numbers you hear only include one step along the charging chain. Usually the efficiency of the on-board-charger itself is meant when people talk about "96%" efficient charging. And you can be sure that the total charging efficiency of the upcoming Tesla Robotaxi is much less than "90%". MKBHD might be right after all...

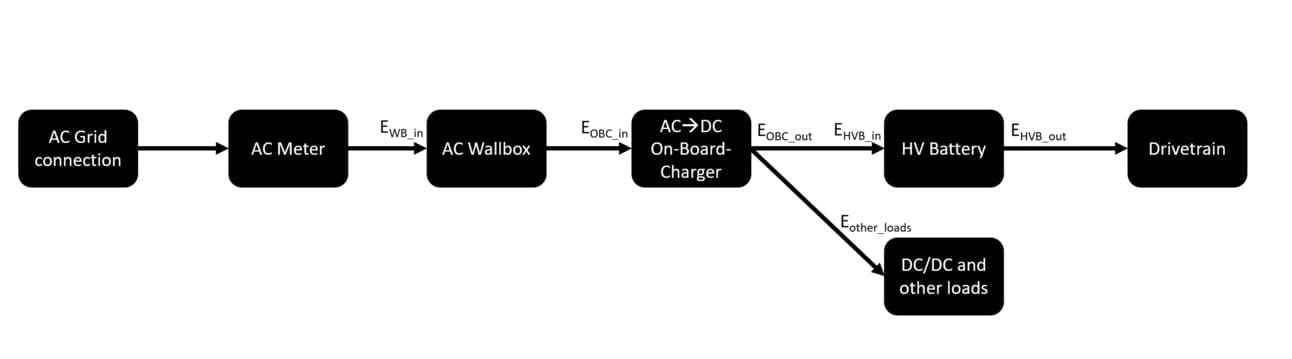

Charging efficiency must include all relevant losses and steps

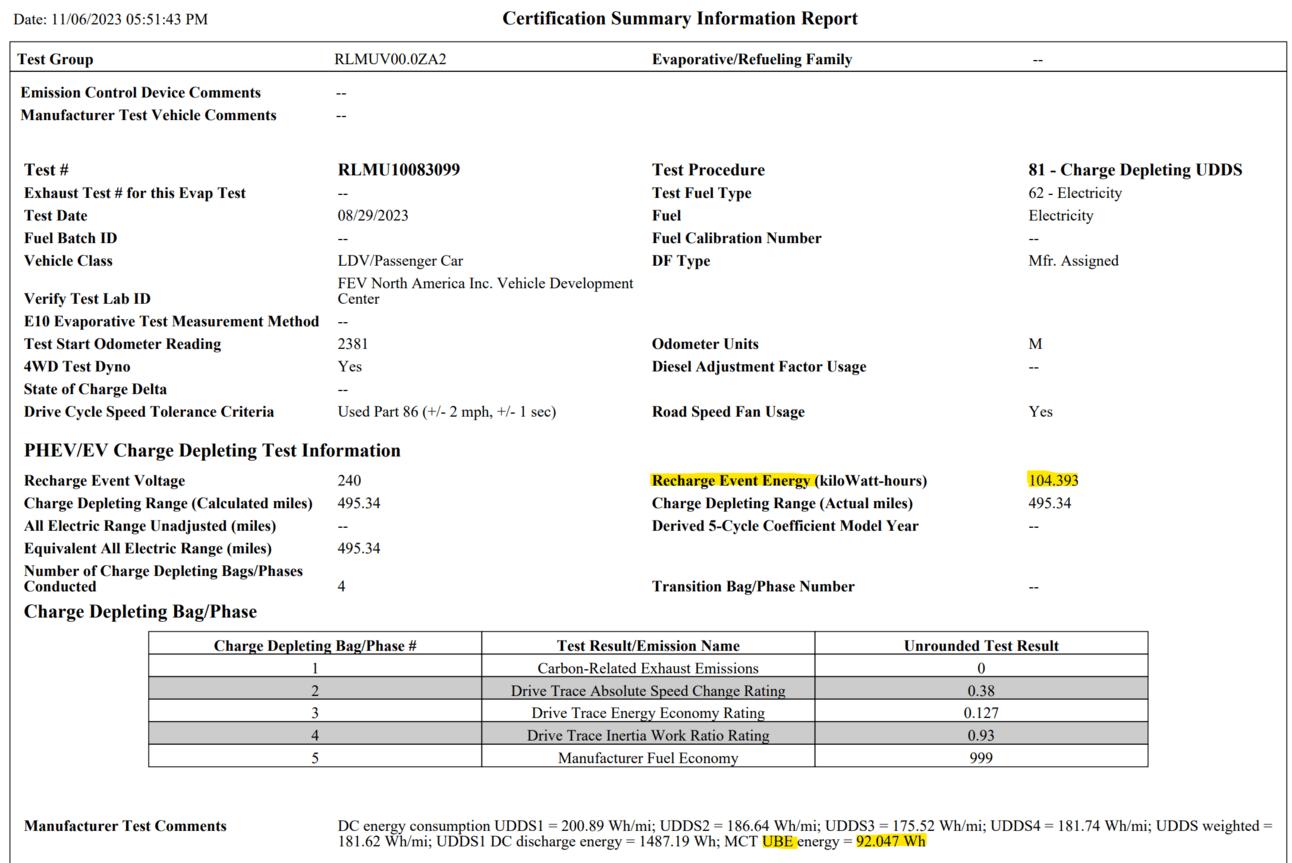

The US Environmental Protection Agency (EPA) thankfully has a suitable test procedure and every manufacturer must publish the 2 relevant data points, that enable you to calculate the real charging efficiency: Usable Battery Energy (UBE) and Recharge Energy Event. Usable Battery Energy is the amount of DC kWh that can be fully discharged during the EPA test cycle until the vehicle cannot drive anymore (independent of what the shown State of Charge (SoC) or remaining range is). The driving cycle and in particular the battery temperature and discharging speed (C-Rate) have a large effect on the voltage at which the electrons can be extracted from a battery. A warm battery discharged very slowly will be able to deliver much more energy than a cold battery that is discharged quickly. But thankfully, these variables are controlled for during an EPA test cycle. The OEM installs special measurement equipment (current sensors) at the battery outlet to measure UBE.

To calculate the charging efficiency, we need to know how many AC kWh we need to put into the vehicle to be able to extract the usable battery energy again. This is called Recharge Energy Event in the EPA documents. The OEM can choose which charging equipment to fully recharge the vehicle from empty to full (“0” to ”100%” customer SOC). Based on the freedom to choose the setup preferred by the OEM, we can assume the conditions are as close to optimal as possible for every EPA-tested vehicle. A calibrated AC energy meter is installed in front of the charging cable or wallbox being used, so the measurement includes all relevant charging losses (except self discharge). Notably, the battery temperature typically rises during a charging event. This warming is energy that flowed into the battery, but did not get stored. Interested in more details about the EPA test? Check out all the recorded data points for each EV at this website: dis.epa.gov. Check out the Screenshot below to see an example from Lucid: https://dis.epa.gov/otaqpub/display_file.jsp?docid=58903&flag=1.

In Europe, the “Worldwide Harmonized Light Vehicles Test Procedure”, in short WLTP, is used. The WLTP test cycle also produces the necessary data points, however these are unfortunately not published centrally. The consumption value in kWh/100km however does include charging losses. The Usable Battery Energy is not necessarily identical to the “usable energy” that some OEMs also include on their spec sheet. Usually, the real UBE is larger, but the OEM wants to include a margin of error since each battery has a slightly different UBE when it comes off the production line. The EPA data is not affected by this inaccuracy.

So what does the EPA data show?

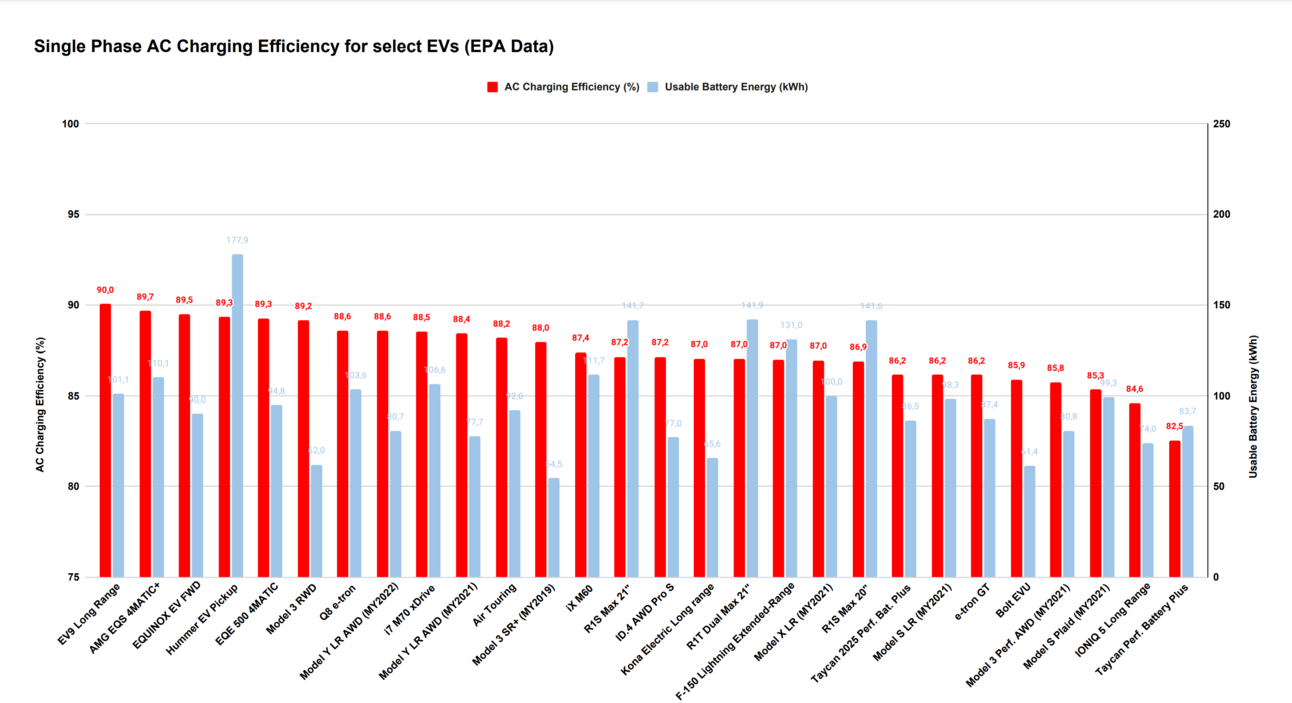

The diagram below shows the charging efficiency of various EVs that are for sale in the US.

Based on the data, we can observe the following key findings:

AC-Charging efficiency losses are significant: Most cars fall in the 85% to 90% efficiency range. At the average efficiency of 87.5%, over 1.2 kWh gets lost for each 10 kWh you pay for.

Single-phase charging is less efficient (most infrastructure in the U.S.) than three-phase (EU) charging: Bad news for most EV drivers in the U.S. On average, charging the same vehicles in the EU will be about 1-2 percentage points more efficient than in the U.S. (See next chapter)

Some OEMs are better than others: Hyundai shows that it is possible to have a bidirectional OBC and still have great efficiency. Mercedes also seems to know what they are doing. Honourable mention to the Hummer EV being in the top 5.

You can check further cars not listed here by going to https://dis.epa.gov/otaqpub/ and searching for your car model.

You may be wasting over 100 € per year by not upgrading to a wallbox

EPA data highlights the charging efficiency at the on-board charger's maximum AC power capacity. Charging at lower speeds requires the vehicle to remain active for an extended period (“stay awake”), leading to a noticeable increase in baseline power consumption. This consumption can range from 100 to 400 watts based on the vehicle's low-voltage system design and controller configuration.

As shown in the chart, charging on a typical European household outlet at only 2.3 kW (1x230Vx10A) has an efficiency of just 84%. Using a three phase wallbox and charging at 6,9 kW (3x230Vx10A) increases that number to 93%. Note that these values are calculated from the AC input in front of the mobile charging cable until the energy actually stored into the battery as reported by the vehicle. The EPA measures slightly more conservative as it also includes any discharge losses. See my master's thesis for full details: A comprehensive comparison of PV-optimized charging strategies for electric vehicles

Data from my master's thesis

Let’s do a calculation for a real-world scenario. To cover 15.000 km per year, an average vehicle (consumption of 20 kWh / 100 km) requires about 3.000 kWh. Let’s compare the required energy to recharge the usable energy based on two charging scenarios:

Charge at 2.3 kW -> 3,571 kWh required

Charge at 6.9 kW -> 3,226 kWh required

The difference is about 345 kWh which needs to be charged on top. We can also translate this into real costs for the EV driver. Assuming a price of 30ct / kWh, this will add to about 100€ per year! Consequently, there is a positive cost-saving case to upgrade your household or workplace outlet with a higher power wallbox.

And there is one more advantage: smart charging! With the increasing AC charging speed, charging can be scheduled and steered. This unlocks two types of flexibility.

Unlocking temporal flexibility: Pause charging in times of grid constraints to reduce the load

Cost-optimized charging: Dynamic electric tariffs provide an incentive to charge within cheap hours and can save up to 30% (ca. 290€) of an EV driver’s electricity bill.

Other researchers have measured similar charging efficiencies. For example Mattia Marinelli and Kristian Sevdari and others have performed high quality tests under laboratory conditions and have measured the values shown below. See this post for more info. This paper is an in depth analysis of on-board charger efficiencies.

What the graph also shows is that charging at typical US household outlet speeds or typical PV surplus charging power (PV Power minus household load) of ca. 1.4 kW is very inefficient at just 65% (Peugeot e-208) or 77% (Tesla Model Y). At some point it becomes cheaper to just export the PV surplus or import power to charge at higher speeds and get a better efficiency. See my master's thesis for a useful formula.

Death sentence for Bidirectional Vehicle to Home (V2H)?

Assuming the average charging efficiency across all models of 87,5% both for charging and discharging leads to a round-trip efficiency of 76,6%, which means for every 10 kWh discharged, 13,1 kWh had to be charged in the first place. Unfortunately, this assumption is only valid for full power discharge into the grid. Vehicle to Home applications only need to cover the current power demand of the house in the range of 1-3 kW. At these discharging powers, the charging efficiency significantly drops off into the range of 65 to 85%, further reducing the round-trip efficiency. The very insightful final report from FFE with BMW and Kostal and sponsored by the German Government found that (DC) V2H applications had an low efficiency. “The data from the pilot showed that the average round trip efficiency was 55% for the PV-Use case” is what the report stated on page 66. (https://www.ffe.de/wp-content/uploads/2023/03/BDL-Abschlussbericht.pdf)

Unfortunately, simply relocating the DC to AC conversion to a DC bidirectional wallbox does not solve the problem. If anything, these systems should be in total a little bit less efficient due to the additional cooling system required in the DC wallbox. Most of the controllers inside the vehicle need to be active, just like in the AC discharging situation.

I am unsure how much charging efficiencies at low power can be improved to levels that make bidirectional charging financially sensible. While home energy storage batteries show how high efficiencies can be achieved, great engineering efforts need to go into making vehicles consume less power while charging. PV surplus and V2H charging might be the simplest use-case, but don't make sense at current round trip efficiencies. Discharging at full power into the grid with ca. 76% round trip (not including any self discharging losses) might make sense for grid services that pay for providing the backup power without actually the need of delivering it every time, like black start capabilities.

More focus should be placed on unidirectional smart charging and unidirectional grid services, which will be a great asset to the grid if we use them right. In the end, telling one EV to discharge into the grid has the same effect on the grid as telling two EVs to stop charging.

In no way is this a criticism of EVs in general, but hopefully a wake-up call to make EVs and the electricity system they interact with even better.

Next time: DC charging efficiency

If you found this topic interesting, let me know if you want to learn about DC fast charging efficiency. But be warned: It could surprise you even more...

What do you think about charging efficiency and its effects on V2G business models?

Leave us a comment on the post online.

This week’s newsletter is brought to you by S44 Energy.

S44 Energy is redefining EV charging with CitrineOS—the open-source Charge Station Management System (CSMS) for the future.

Featuring full OCPP 2.0.1 implementation, API-based architecture, OCPI roaming support for CPOs, and modular design, CitrineOS surpasses traditional SaaS and closed solutions.

As a Linux Foundation Energy Project, CitrineOS empowers organizations to build innovative, cost-effective charging infrastructure without ongoing fees or restrictions.

Learn more at S44.team

3 Links 🔗

OCPP goes IEC✉️: On October 20th, the IEC published the approval of the Open Charge Point Protocol (OCPP) as an IEC International Standard IEC 63584! This marks a significant milestone in the recognition of OCPP across the globe. (Link)

Renault/TMH V2G goes live in France🔁: TheMobilityHouse, Renault and Mobilize just announced that it’s AC V2G offering is now live in front of customers in France. To our knowledge, this marks the first time that an AC V2G service in Europe goes beyond pilot stage, into open customer rollout (allegedly). We’ll keep our eyes out for the first user reports! (Link)

Scout teases "Retro-Rivians"🚗 : Scout, a US-based electric vehicle brand owned by Volkswagen Group, just released its first two concept vehicles. The Terra Pickup Truck and Traveler SUV seem inspired by traditional designs like the Ford F150 pick and the Ford Bronco SUV, but also clearly borrow some exterior aspects from Rivian’s R1T and R1S and add a retro throwback to the original Scout SUV’s from the 1970s. Underpinned by a 900V platform (courtesy of VW group most likely) and a multi-zonal E/E architecture (see Rivian x VW joint venture in ⚡ Did VW and Rivian just have a baby?👶 ), these vehicles could be interesting additions to the US EV market. But we’ll have to wait until start of production in 2027 to find out more. (Link to Scout Motors Reveal event video)

Most-clicked link last week: Was the Youtube review NIO’s new budget EV SUV model, the ONVO L60:

Meme of the Week 🤡

🤣

Reader Review of the Week

Selected ⚡️ You didn’t bring the heat on ⚡Onvo L60 review, EVBox shuts down and wrote:

“Just nothing really new”

That's a wrap for this week! Let us know how you feel and leave some feedback (We read every single one of these 🙂 ):

What do you think of today´s edition?

Someone forwarded this to you? Subscribe now - it's free!

DISCLAIMER: None of this is financial or tax advice. This newsletter is strictly educational and is not investment advice or a solicitation to buy or sell any assets or to make any financial decisions. The Electric Avenue team may hold investments in or may otherwise be affiliated with the companies discussed.